Equipment

To develop and manufacture the best quality of our optical and mechanical products, we are progressively investing in new equipments and updating our production lines.

Design

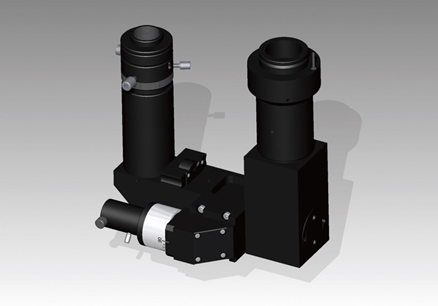

3D CAD Design

Enable to verify and analyze the shapes, interferences and structures. Interfering parts can be found in both stationary and operating conditions, while proceeding the design. Proposal that incorporates design requirements collected in advance, examines each factor of space, strength, resistance, and cost, and performs analysis simulation can be provided.

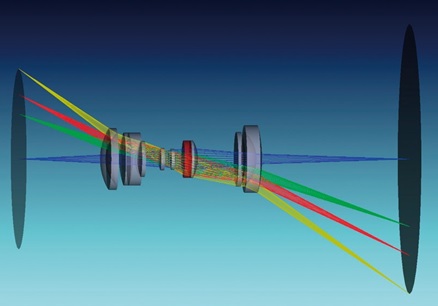

Optical Design

Enable to provide optical design with right optical material property of custom requirements optical lens and optical parts.

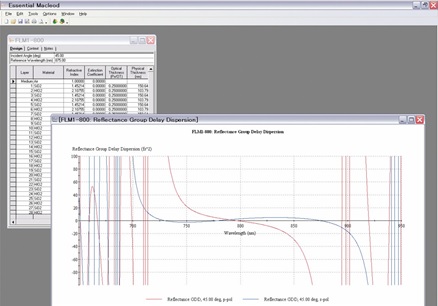

Coating Design

The optimum simulation is presented to the customer for the requested optical characteristics. Based on the simulation, various types of coating processes and thin-film deposition systems are utilized to achieve required optical characteristics.

Processing

5-axis Machining Center

Enable to process diverse shapes of product.

CNC Lens Polishing Machine

Enable to polish the high precision lenses at a high speed.

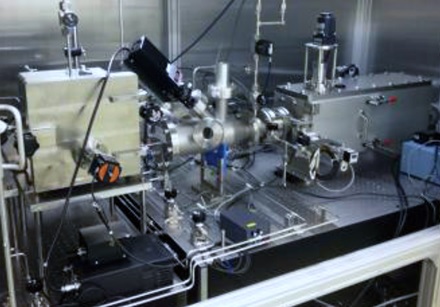

IBS(Ion-Beam-Sputter)

Enable to realize a high precision optics with high reflectivity, high damage threshold and low scattering optics.

Ring Polisher

Machine Polish the flat surface of Mirror, Prism to reach a high surface accuracy.

Near Field Etching system

Using a dry non contact etching system to enable to achieve Ra < 1Å surface on optics.

Ion Assisted Deposition System

Enable to have the deposited layer with a higher density and a more compact structure.

CNC Lathe Machine

the lens tubes or round shape parts to the center of optical axis, and possible to machine the hole and angle with high-accuracy positioning at once.

Ultrasonic Cleaning Machine

Wash the substrates before coating.

Magneto-Rheological Finishing

Magnetic materials and abrasives whose viscoelasticity is enhanced by a magnetic field are used in this polishing technique. The magnetic effect controls the contact with the workpiece surface, enabling extremely high-precision finish polishing.

Wire EDM machine

Process the micro shape by wire electrical discharge machining.

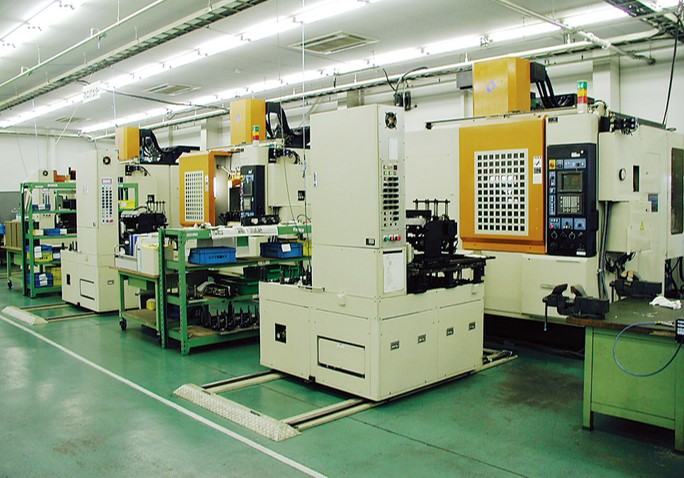

Horizontal Milling Machine

Many kinds of machining tools are equipped for various productions and manufacture intricately-shaped mass-production items.

Vertical Milling Machining

Used for processing the parts of a wide variety of lots.

Inspection and Evaluation

Spectrophotometer

To analyze spectra-characteristics of material in the range from ultraviolet to infrared.

Scanning Electron Microscope

Possible to measure and estimate the surface structure or to run the elemental analysis which covered the weak point of optical microscope.

3D Optical Surface profiler

Characterizing and quantifying the surface roughness and the micro shape of the substrate.

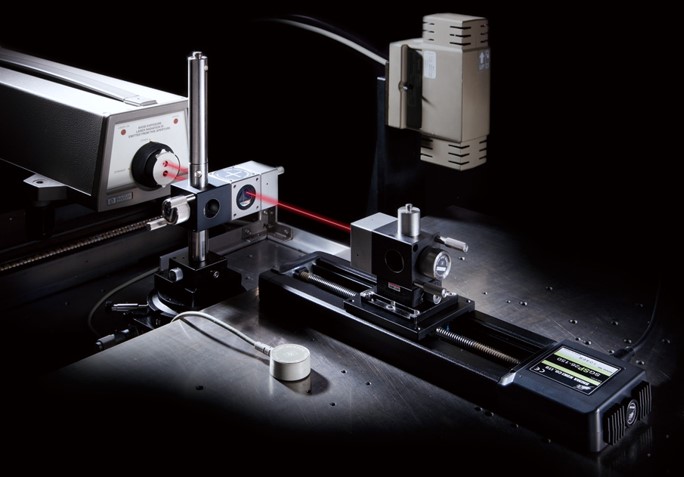

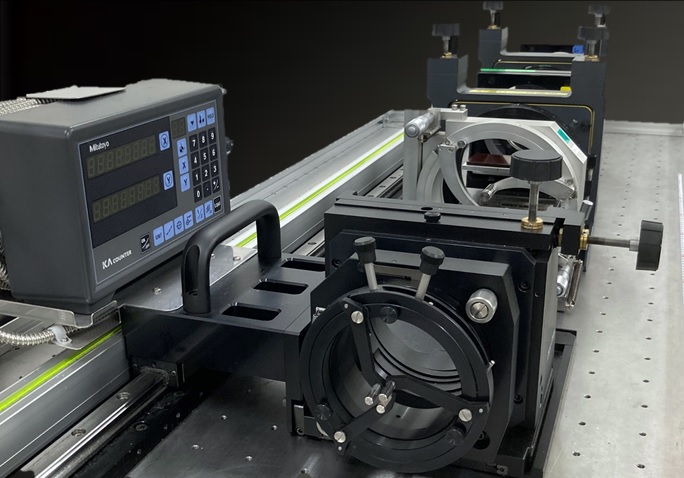

Laser Calibration System

To measure the positional accuracy, the position repeatability and the lost motion of the motorized linear stages.

AFM(Atomic Force microscope)

It is a type of microscope to detect the atomic force acting on the probe and the sample and it is possible to measure the surface shape of the sub-nanometer.

Focometer

To measure the accuracy of the focal length of spherical lens.

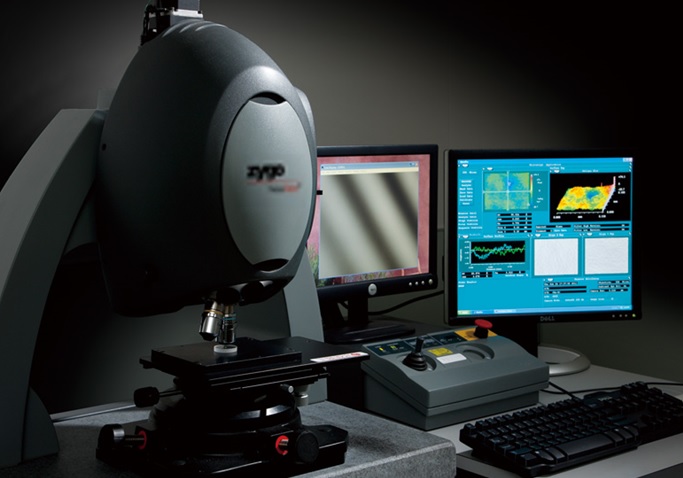

Zygo® Laser Interferometer

Using Zygo® interferometer system to measure, estimate and guarantee the surface flatness of master optics.

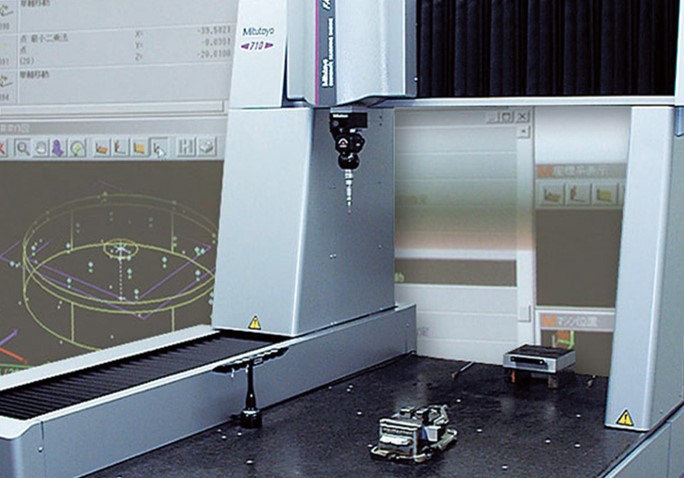

3D Measurement Machine

To measure and estimate the complex 3D shapes of parts and products.

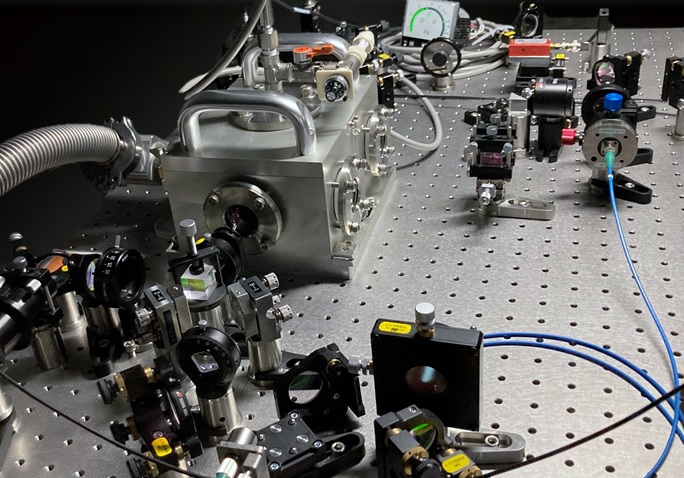

CRD(Cavity Ring-Down)

Measuring the lifetime of photons stored in the Fabry-Perot resonator, and measure the reflection of high-reflective mirror.

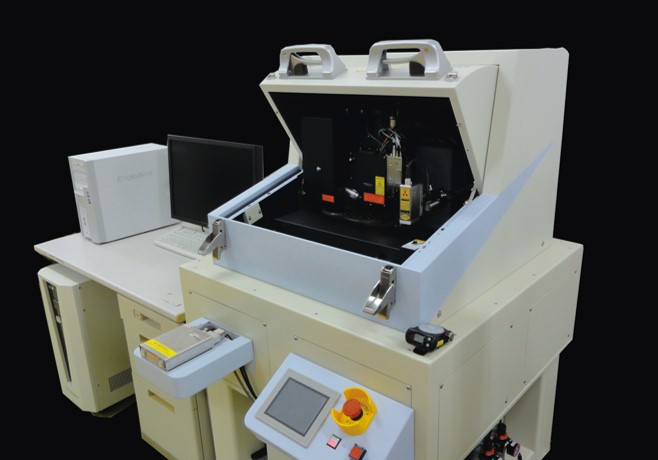

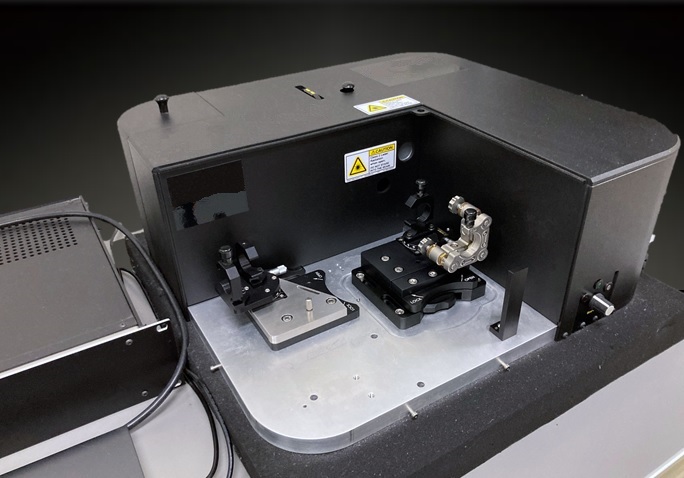

Dispersion Measurement System

The highly accurate and reliable time domain white light interferometry (WLI) is used in this measurement system. Group delay dispersion (GDD) characterization of reflection and transmission type optics for femtosecond lasers can be performed.

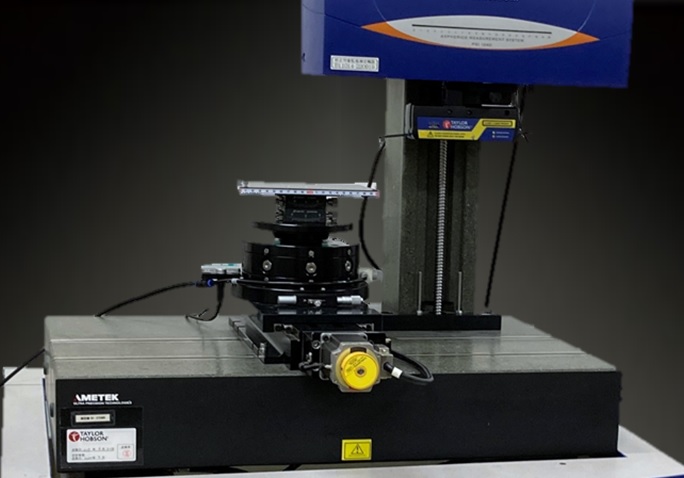

Surface Roughness Tester

A test system capable of measuring surface roughness and contour shape, mainly used for ultra-precision surface profile and roughness measurements.